Rapid Low Volume Extrusion Services

1 to 1000+ Metal and Plastic Parts

Global delivery as fast as 2~3 weeks

Aluminum & Plastic Extrusion

If you are looking for an extrusion profile cut in a certain length and the volume you require is high, you should definitely go with an extrusion company directly. There are lots of extrusion companies dealing with high-volume production. Though, these companies are not willing to handle low-volume aluminum & plastic extrusion projects, unless you are one of their VIP customers. so it is very difficult get prototype aluminum extrusions & prototype plastic extrusions.

At Mester, we have solid partners for short run custom aluminum extrusions & short run plastic extrusion services. They take good care of our projects, both in quality and lead times. We also routinely do quality control on your project before shipment.

Compared with traditional extrusion companies, we have a large amount of CNC machines, so we can do precision post-machining in house.

Mester Advantages

There are huge amount of extrusion service providers. Why choose us?

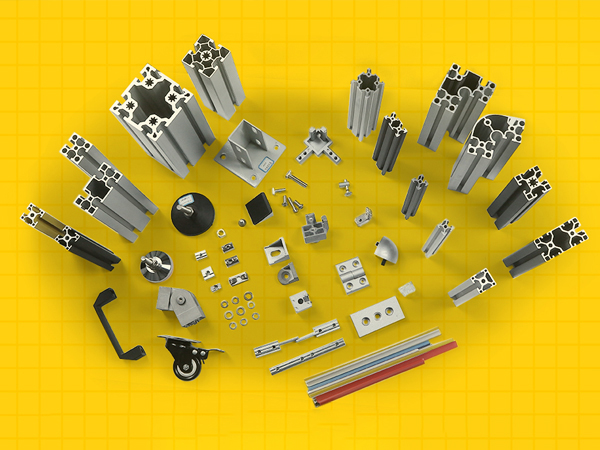

Mester offers both aluminum extrusion and plastic extrusion services to transform aluminum alloys and high-quality plastics into specified shapes that meet your specifications. If you need rapid prototyping or low-volume manufactured products with a definitive cross-sectional profile, then extrusion is definitely for you.

The process starts with selecting a design that will be functional as well as durable. Our team of designers here at Mester is adept at creating designs. We consult with our customers in order to figure out the correct extrusion shape, assembly protocols, weight reduction, and to make sure parts meet full functionality.

After this strategic design process is complete, we begin creating your design from either plastic or aluminum alloys, depending on your requirement. Appearance is also high on our list since it is our aim to create parts that not only work well but look great too.

Common Extrusion Applications

Aerospace

Automotive

Trains

Ships

Construction Industry

Medical Devices

Display Industry

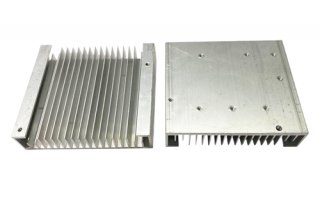

Heatsink

Electronics

Automation

Aluminum Extrusion Surface Finishes

| As Machined (standard) | ~125 RA µin (3.2 RA µm). Minor tool marks will be visible on the part. Surface finish requirements can be increased to 63, 32, or 16 RA µin. |

| Bead Blast | Matte finish with light texture is achieved by blowing small glass beads against the part. |

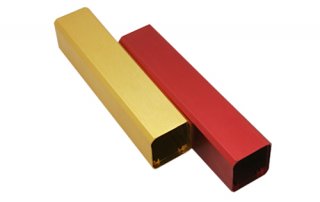

| Anodizing Type II | Corrosion resistant finish. A variety of different colors can be applied when anodizing. |

| Anodizing Type III | Adds a wear resistant layer on top of the corrosion resistance of Type II. |

| Powder Coat | Strong, wear and corrosion resistant finish, that is more durable than the methods mentioned above. Powder coat finishing are available in large range of colors. |

Other surface finishes are available upon request, for more please see our surface finishing services.

Aluminum & Plastic Extrusion FAQ

Why should I use Mester over a dedicated extrusion company?

We specialize in low-volume manufacturing. If you require a small to medium-size order, other companies may not accommodate your needs.

Can I specify an aluminum alloy?

Our most commonly used alloys are 6061 and 6063, which contain high levels of magnesium and silicone. Both are highly corrosion resistant.

You may specify a different aluminum alloy, and we will review the feasibility when providing you with a quotation.

Who manufactures the extrusions? We have a selection of trusted extrusion partners who fulfill our orders, but Mester will do post-machining and check the parts before shipment.

Custom Low Volume Extrusion Services

Plastic Extrusion

Plastic materials include polystyrene, nylon, polypropylene, and polythene. These are thermoplastics: they are heated and then pressured in a mold which can form them into different shapes and sections.

Aluminum Extrusion

Aluminum extrusion is defined as the process of shaping aluminum material by forcing it to flow through a shaped opening in a die. Aluminum material emerges as an elongated piece with the same profile. Alloys we commonly work with include: 6061, 6063.

Aluminum & Plastic Extrusion