Various Kind of Options Available

Production Level Surface Finishing

For Both Metal and Plastic Parts

Surface Finishing

Surface finishing refers to different processes used to alter the surface of a manufactured product to give it a distinct or desired look and feel. Different techniques are used to improve the appearance, adherence, solderability, resistance to corrosion, hardness, conductivity and many other characteristics of industrial components.

Mester offers a high quality surface finishing service for all components and parts regardless of the machining method used in producing them. We have some skilled experts who only handle finishing assignments so the quality of work done on your products is of exceptional quality. If you desire a perfect finish for your prototypes and other manufactured components get in touch with our customer services team for a quick and accurate quotation.

What you can get from us?

Sanding & polishing is one of the most common finish for prototyping. Sanding is very basic process to remove cutting marks or the printing marks, in order to get smooth surface. Get ready for further finish such as sandblasted, painted, chromed…

Started from rough sand paper, when you reach 2000 sand paper the part surface are smooth enough for high gloss polishing to obtain shiny surface or mirror look, transparent such as light guide, lens.

Painting is a very flexible way to create different surface appearance.

We can achieve:

- Matt

- Satin

- High Gloss

- Texture (Light & Heavy)

- Soft Touch ( Rubber Like)

The CD thread is similar to the pattern of a CD disc, which is obtained by using a sophisticated CD pattern machine to remove material on the metal surface. Its pattern spacing is determined by the appearance and size of the product.

Material suit for CD thread:

- Carbon Steel

- Stainless Steel

- Brass

- Copper

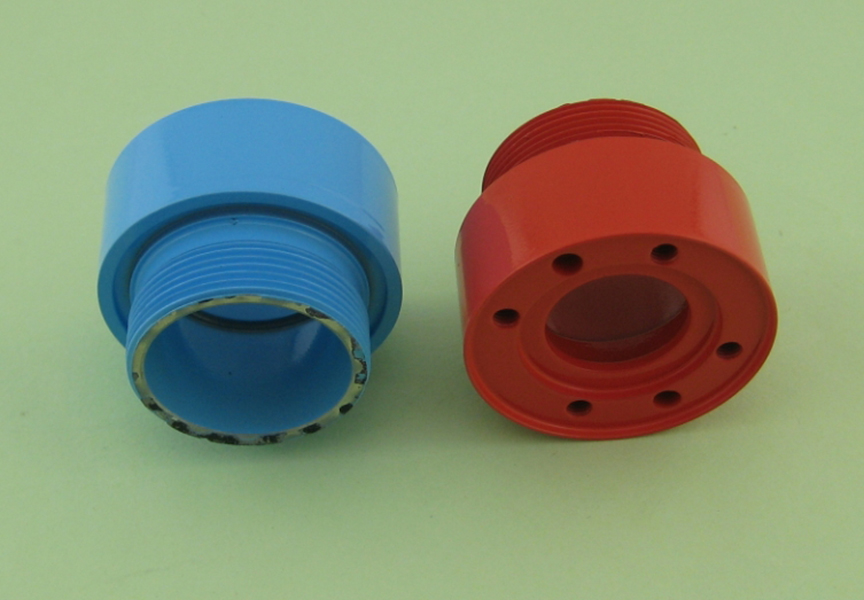

The most popular way to create decent surface for electronic products. Apple almost use anodized for all their products.

We are offering:

- Anodized Type 1

- Anodized Type 2

- Anodized Type 3

- Chemical Film/Alodine

These type of finish is only create protect layer, but also a super look.

- Chromed

- Metallizing

- Gold plated

- Silver plated

- Color Plating

- Zinc Plating

- Tinning

- Copper and brass plated

- Antique brass plated

Sanding & polishing is one of the most common finish for prototyping. Sanding is very basic process to remove cutting marks or the printing marks, in order to get smooth surface. Get ready for further finish such as sandblasted, painted, chromed…

Started from rough sand paper, when you reach 2000 sand paper the part surface are smooth enough for high gloss polishing to obtain shiny surface or mirror look, transparent such as light guide, lens.

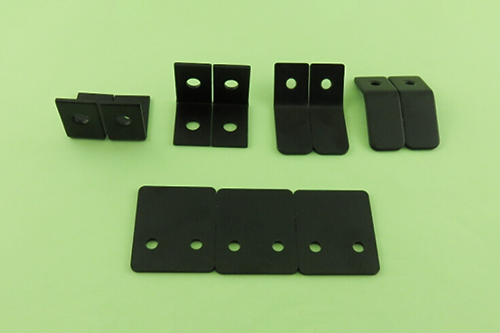

Eletrophoresis – also known as electrocoating, e-coating, electrophoretic coating, catophoretic painting, etc – is a special coating technique, and it is one of the most commonly used methods for coating of metal workpieces. The E-coat process was originally developed for applying an anti-corrosive coating over steel car bodies.

It is similar to painting. There are following advantages of eletrophoresis: the finish is very glossy or matt, very smooth, looks very high-grade. Meanwhile, no overspray problem, Insulated racks are not coated,Controlled and consistent thickness, easy to be faded after friction with clothes is its disadvatange.

There are various way to create logo, symbol and text on your prototypes or production parts.

We can offer:

- Silk-Screen

- Pad Printing

- Rub on

- Laser Engraving

We are also providing:

- Sandblasted & Bead blasted

- Heat treatment

- Blacking

- Water Transfer

- Polished

- CD thread

- PVD coating

- Dacromat

- Welding